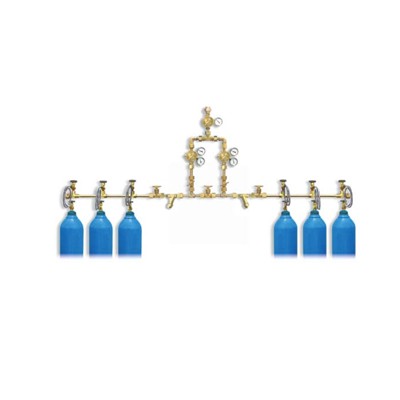

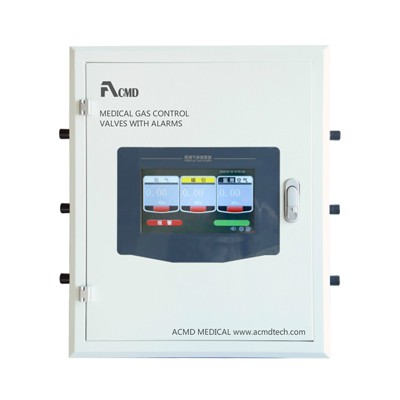

ACMD automatic manifold system is design to provide continuous gas supply without any manual operation. It is mainly for small and medium-sized gas supply depot. Several cylinders centrally connect with manifold pipe, after depressurization and stabilizing and delivery medical gas to terminal use.